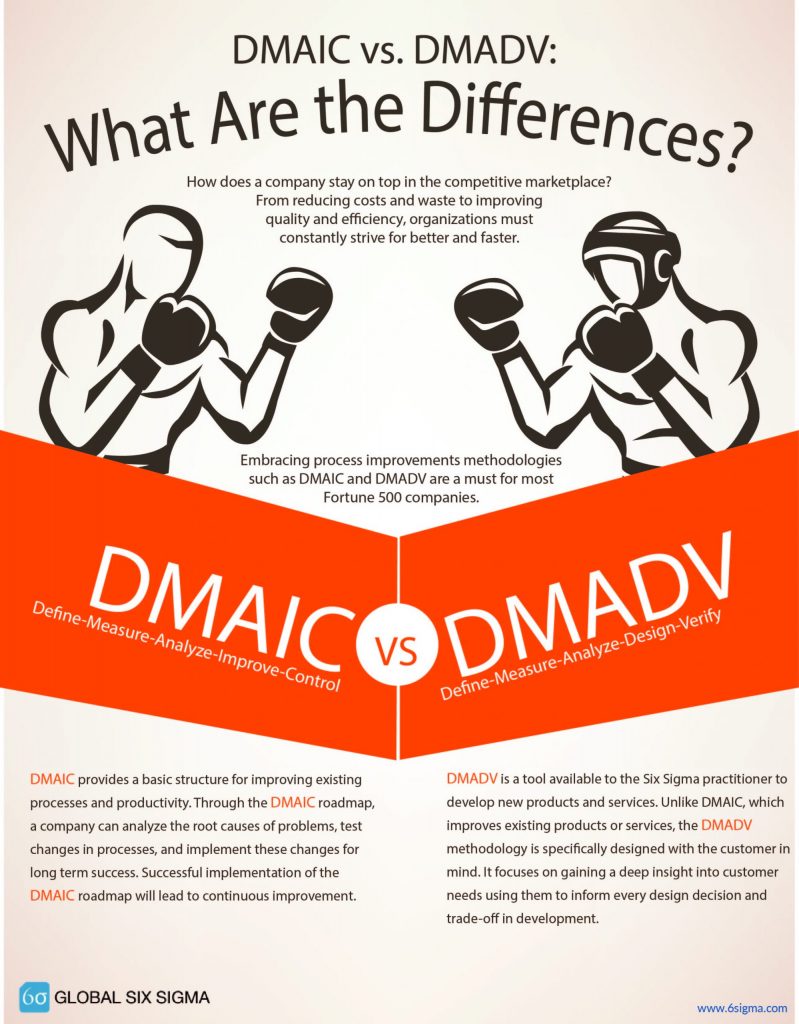

Want to understand the differences between DMAIC and DMADV? Check out our infographic below for a breakdown.

DMAIC (Define-Measure-Analyze-Improve-Control)

If you have an existing product or service that doesn’t quite meet the requirements of your customers and you want to improve the existing processes then you need to use DMAIC.

D: Define the problem, goal, reason the issue needs to be resolved.

M: Measure the current status and use it as a baseline.

A: Analyze the root cause, identify with data driven tools and validate as to why the issue is occurring.

I: Improve and identify some creative solutions to get rid of the major root causes, so the problem will be fixed and prevent future similar issues.

C: Control and sustain the success of the new improvements.

DMADV (Define-Measure-Analyze-Design-Verify)

This is the acronym for the philosophy used in Design For Six Sigma (DFSS), used when developing a brand new service or product within a business.

D: Define the goal of the new product or service, set realistic and measurable goals.

M: Measure and know which factors are critically important. This should include any parameters, including risks, also accessing the production process and product capability.

A: Analyze, develop and design alternatives; work with different combinations and their results, selecting the best combinations.

D: Design a detailed prototype; create and modify until all the errors are worked out.

V: Verify as the final step. The newly designed product is taken to the real world and tested to see if it would work perfectly.

No responses / comments so far.