Standard Work in Lean Six Sigma is a very misunderstood topic. We explain Standard Work in this video and show you how to begin applying this principle today.

Taiichi Ohno is credited with having said:

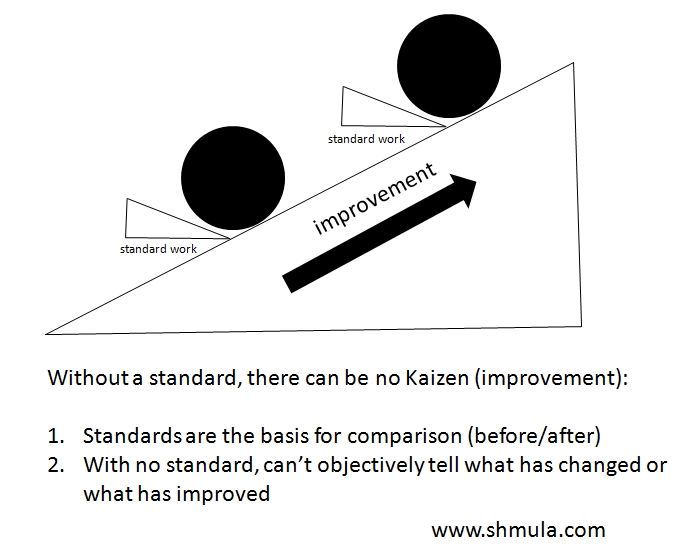

When there is no standard, there is no Kaizen

In other words, when a process is performed unsystematically in different ways, then:

- There can be no basis for comparison (before/after)

- One cannot objectively tell if there was a difference or change

- No improvement is possible in regards to Time, Quality, Quantity, Cost, etc.

In this 5:36 minute video, we cover the following topics:

- What is Standardization

- Why is Standardization Important?

- View an example of a Standard Work Instruction Sheet – a practical element in the practice of Standard Work.

Download a Standard Work Instruction Template

What is Standard Work?

Pictorially, a standard is a wedge in this diagram:

The ball represents the process we’re trying to improve. The uphill picture represents improvement. So, at each improved process, that becomes the new standard. When the process is improved, then the standard is updated.

Where there is no standard, there is no Kaizen. This is true because variation, which invites defects and errors, continues to thrive in an environment where no standard is followed.

An important note: The concept of Positive Variance is an important but not discussed topic in Lean Manufacturing – but a well-rounded and good understanding of Standard Work requires understanding Positive Variance.

Standard Work Video

[contentblock id=16 img=gcb.png]

Comments are disabled for this post.