Integrating or reconciling the PDCA framework from Lean and DMAIC from Six Sigma is the topic of this post. How is the PDCA Cycle similar or difference from the DMAIC of Six Sigma?

Since both methodologies and frameworks share a common history, it is no surprise that integrating their respective frameworks was not difficult to do.

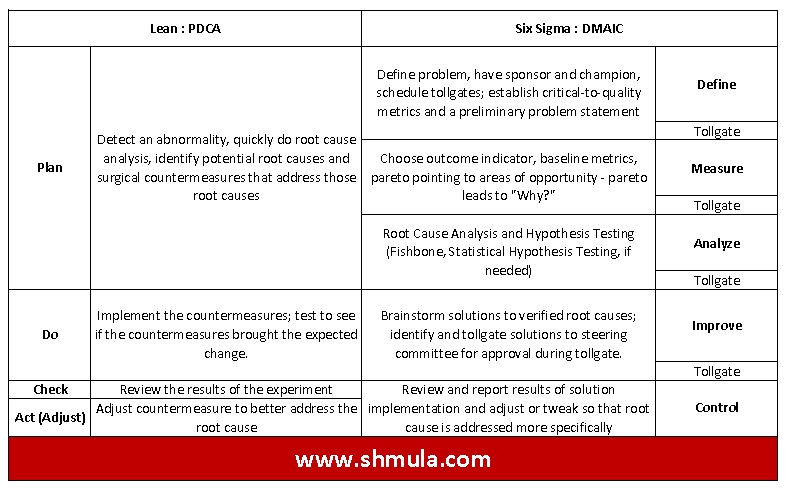

Below is my attempt at exactly that. Below the PDCA and DMAIC comparison chart, I’ll explain some big and some subtle differences.

Now, on to some differences between DMAIC and PDCA:

Differences Between PDCA and DMAIC

Visually, PDCA has 4 steps, while DMAIC has 5. But, it’s not just 5 steps, but 5 steps and tollgates in between each phase. A tollgate is where the project team or team leader presents his or her findings in the current phase and the steering committee will either approve the project to move to the next phase or not.

A big difference between PDCA and DMAIC is the corporate infrastructure required. Six Sigma and the DMAIC methodology in which its work is carried out, requires a steering committee, tollgates, a champion, and a project sponsor.

While all those might be good, given the right context, the organizational burden on a company is real because it requires up-front investment of time, resources, and attention.

On the other hand, the PDCA framework of Lean is completed many, many times without much hoopla or fanfare. Indeed, the PDCA framework of Lean allows for the involvement of everybody, whereas DMAIC of Six Sigma requires specialized and trained people, often called Black Belts, Green Belts, or Master Black Belts.

There are no belts in Lean; the mindset of Lean and the tools it uses to carry out its work is highly accessible to everybody – no belt required. No barriers to entry or barriers to participate, just some training, ongoing training, and a lot of hands-on doing.

So, in our compare and contrast of PDCA versus DMAIC, they are quite similar, except for the organizational infrastructure required in Six Sigma.

Because of the differences I note above, the benefits of Lean and the PDCA framework is often heralded because of its speed and velocity. This is true, because there is no organizational overhead and improvements are made – many, many small improvements – daily.

It’s Your Turn

Given the context and the company and the needs of the organization, consider the differences and the commonalities between Lean and Six Sigma. Where one might meet your needs, the other might not be right for you. You decide.

What do you think? Please share your opinion on the differences between Lean and Six Sigma.

[contentblock id=16 img=gcb.png]

Comments are disabled for this post.