The Red Bead Experiment is a metaphor for problems, where the red beads represent “bad” and white represent “good”. It is a teaching tool mostly used in manufacturing or instruction in quality management. The Red Bead Experiment was created by Dr. W. Edwards Deming, the person who influenced Toyota who, later, would develop The Toyota Production System.

This post explains how to play the Red Bead Experiment, the Lessons Learned from the Red Bead Experiment, and how to facilitate the Red Bead Experiment. This post also contains a video tutorial of the Red Bead Experiment. This is Part 1 of 6 of the Red Bead Experiment.

How To Play The Red Bead Experiment

The Red Bead Experiment consist of a large bowl with white beads and red beads and a paddle. Each player draws the paddle full of beads. Here are the specific rules for the game:

- Objective: Produce white beads and avoid producing red beads (defects).

- Instructor: Plays the role of the manager.

- Quality Manager: This person counts the number of red beads after each draw.

- Controller: This person records the number of red beads as relayed by the Quality Manager.

- Workers: Have as many workers as you desire, but aim to keep the game to ~40 minutes.

- Rounds: Try to have several rounds, where a round is defined as each worker has had a turn to scoop the paddle into the bowl of beads. In each round, as the manager, play the following roles:

- Round 1: Manager sets target for no more than 5 red beads. If violated, worker will have to work 2 hours overtime without pay.

- Round 2: Manager introduces a bonus program where the worker that produces below 5 red beads will receive a $500.00 bonus.

- Round 3: Manager is mean – yells, belittles, threatens, compares workers to each other, and has a big temper.

- Why the Rounds: The rounds are meant to show the futility of such management approaches of bonuses, threats, and other incentives. No matter what the motivational approach, producing fewer than 5 red beads is futile.

Red Bead Experiment – Data Analysis

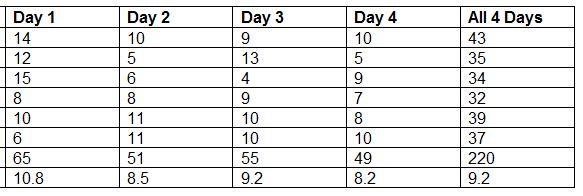

After several rounds, the Controller should have a table that looks like the following:

The bottom row shows the average of red beads per worker per day.

The instructor can then use this data set to introduce the class to statistical process control, variation, common cause variation, special cause variation, and upper limits and lower limits.

Red Bead Experiment Video Tutorial

Below is a video tutorial of the Red Bead Experiment. This video is Part 1 of 6.

Now, onto lessons-learned.

Red Bead Experiment – Lessons Learned

- All variation comes from the process.

- There was no evidence than any worker was better than the other.

- The workers were doing their best, yet they were not improving – could not improve.

- Intimidation, bullying, did not help the workers improve.

- Monetary incentives did not help the workers improve.

- All processes have natural variation.

Video Transcript

Narrator: This is Dr. Deming’s red bead experiment. We use it at Hanford to illustrate the five core functions of ISMS, especially feedback. We use volunteers from the audience to produce white beads for the white bead corporation using many modern management techniques such as numerical targets. The number three comes up several times during this exercise. We have monetary incentives and accountability and tabulated reports made to the president of the company.

We also demonstrate some statistics. Many tools get abused and used during this exercise. We hope you find this video useful as a safety meeting topic, or perhaps as “train the trainer” video for those who would like to lead their red bead experiment. We hope you find this experience entertaining but also educational.

Steve: Good morning. I’m Steve Prevette, your foreman. I’d like to welcome all you prospective employees as employees of the White Bead Production Corporation. We do have a new contract at Hanford to produce white beads for the Department of Energy, and as part of your orientation I would like to introduce the president of the company, Mr. Steven Byers.

Steven: Welcome, candidates. We look forward to completing our screening process and selecting a number of workers. As the foreman has mentioned, we do have a new contract. It calls for increased production. We need new workers.

We have used our HR department to screen the candidates and we are confident that we now have a pool of above-average workers only, which is very important of course. With that, I would like to have the foreman select the final candidates, and let’s get started with the production.

Steve: Yes, you all were given pink slips as you entered this room, or some of you were given pink slips at least, the lucky ones. Our job postings are as follows: We need six willing workers. They must be willing to put forth best efforts. Continuity of your job is dependent on your performance, your performance alone.

Educational requirements are minimal and experience in pouring is not necessary. Now there should be six people out there with “Willing Worker” number one, two, three, four, five, and six badges there. Ah, one very excited willing worker there! Come on forth! There’s got to be five other excited, willing workers, so come on down. Line up right along here. One, two, three, four, five, and six.

Oh, we have three not-so-willing workers out there some place. Come on! You’re not making good first impression upon your management. Come on, come on down. Okay, I think we have our six workers. Line up in order, one through six. That’s part of the screening process here, can you count to six?

Of course, the people who really need to count are our keyway inspectors. We have two keyway inspector sheets out there. They must be able to distinguish red from white and be able to count to 20. These people only have to count to six. Experience is not necessary, so my two keyway inspectors, come on forward. Come on up here. Two keyway inspectors.

Steven: You’re a little short on workers.

Steve: I am? Where’d my sixth worker go? I saw six people up. Okay, but inspectors cannot mingle with the workers. Inspectors come over here. These are the two inspector chairs. Now, I do have a sixth willing worker out there. One, two, three, four, five¦ Number three! Who’s got willing worker number three? Okay, I hear Tom [inaudible 00:03:40] is out there. Oh, no, we found our three.

Willing worker number three, take your spot in the third place there. We’re back on track here. Very good. Now we have our keyway department come forward. We kept them separate from the workers because this is very important, and we don’t want the workers to talk either, because that decreases productivity. I will point out our Increase Productivity poster,and if you spend your time talking you are decreasing productivity.

Now I should have an inspector general out there. Inspector general should have the same qualifications as the inspectors, but must have a loud voice, because you talk. Now you come forth and stand behind your two inspectors. You should make sure that they are very ethical people because the quality of our product depends upon our keyway department. I need an accurate count of the beads that we produce, and of course to record that count, there should be a recorder out there. Somebody should have a pink slip that says “recorder.”

Will the recorder please come forward and sit next to the view graph machine here? Ah, very good. Very qualified looking recorder. I’m sure you are good in addition and division, and you must be sharp. Sit right there. Here is your writing utensil, and here is payroll because next thing we must do is record our payroll. We are going to have the willing workers state their first name and spell it, and then I will repeat it to you and you will record it on the sheet. Willing worker number one, your first name?

Curt: Curt, C-U-R-T.

Steve: Say that again?

Curt: Curt, C-U-R-T.

Steve: C-U-R-T. Yes, now you may write it. Willing worker number two?

Marty: Marty, M-A-R-T-Y.

Steve: M-A-R-T-Y. Now my trouble worker here, number three.

Ed: My name is Ed, E-D.

Steve: E-D. Don’t get ahead of me. Now, procedure compliance is very important here, you understand. Don’t get ahead of me. Worker number four?

Debbie: I’m Debbie, D-E-B-B-I-E.

Steve: D-E-B-B¦ Sure it’s not Y?

Debbie: It’s I-E.

Steve: I-E, okay. Willing worker number five?

Ken: Ken, K-E-N.

Steve: K-E-N. And number six?

Sid: Sid, S-I-D.

Steve: S-I-D. Like those simple names. Very good. Very, very good. Okay, we have our payroll. Now of course a very important thing is your on-the-job training. We have a QA program here. We have our Be A Quality Worker poster. I have already pointed out our productivity program. We have a performance incentive to increase productivity. You all understand this? Increase productivity. And of course we have Take Pride in Your Work and Do It Right the First Time.

Get instructions on how to conduct the Red Bead Experiment >>>

[contentblock id=16 img=gcb.png]

Comments are disabled for this post.