In previous posts, we discussed the DMAIC Methodology in Six Sigma. We discuss the previous phases of DMAIC here:

- Define Phase, DMAIC

- Measure Phase, DMAIC

- Analyze Phase, DMAIC

And in this post, we’ll discuss the Improve Phase of DMAIC.

Let’s revisit, from a high-level, the DMAIC storyboard:

In Define, we discuss the problem and make sure to obtain agreement on the problem from the stakeholders. In the Measure Phase, we discuss data collection methods, how to appropriately display information, and how to analyze and synthesize and decide where the team will focus their efforts in the next phase, the Analyze Phase. In the Analyze Phase, we discuss root cause analysis and hypothesis testing.

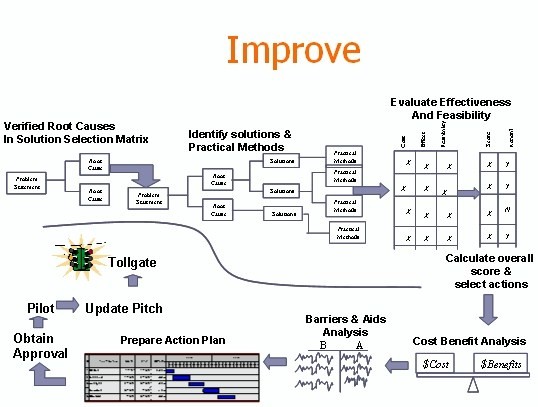

In this phase, the Improve Phase, we assume that root causes were reached and some or most were validated. Given that context, below is the rough outline of the Improve Phase in DMAIC.

Here are some questions that can drive the overall tone of the team in the Improve Phase:

- What possible actions or ideas will help us address the root cause(s) of the problem and achieve our goal?

- Which of these ideas form workable potential solutions?

- Which solution(s) will most likely achieve our goal with the least cost and disruption?

- How do we test our chosen solution to ensure its effectiveness and then implement it permanently?

In the Improve Phase, the work is driven from the assumption that root causes were identified and verified. The next step is to utilize the following tools:

- Solution Selection Matrix: To brainstorm the potential practical methods to address the root causes.

- Action Plan: This is typically a Gantt Chart showing people responsible for which action item and a date by which it should be completed.

- Barriers and Aids Diagram: This is an exercise that shows what the change management challenges might be for implementing the improvements – this will usually contain issues related to people.

- Cost and Benefit Analysis that shows the cost of the project and the potential benefit. In most organizations, this step is completed by both the project lead and the Chief Financial Officer of the site Controller.

For those familiar with Lean Manufacturing, this step should remind you of PDCA – indeed, DMAIC came from the PDCA cycle.

When the items above are completed, then the project team is ready to tollgate the Improve Phase. In the next section, we’ll discuss the last phase in the DMAIC Methodology, the Control Phase.

Comments are disabled for this post.